Our history

Sustainable transport

has been speaking Italian since 1919

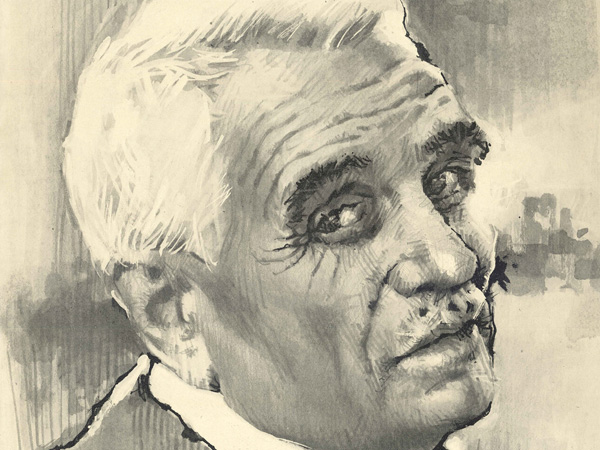

Born in 1879, the sixth of seven children, Ettore Menarini worked for many years in various body shops in Bologna, including one run by Marco Fiorini, which at the time was among the most popular in Italy and mainly built horse-drawn carriages. In 1914, he decided to set up on his own and opened a small body shop with a partner but, at the outbreak of the First World War, he was called up and assigned to workshop duty in the 3rd Mechanised Brigade of the Italian army. On his return to Bologna, he went back to work and, showing remarkable courage, in an Italy which had been victorious but that had been badly damaged by the war, he founded his company, which he decided to call Ditta Menarini and C, even though he was the only owner.

It was 1919. His company was based in a converted barn, in Via del Chiù, and was essentially dedicated to bodywork repairs. Shortly afterwards, at the request of FIAT, the company also moved into production. However, for much of the 1920s, Menarini’s main business was the construction of horse-drawn “touring carriages”, a craft that required time, precision, and a close relationship with the customer, as it took from four to six months to build a carriage.